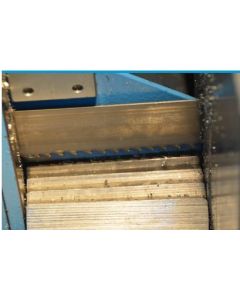

Tungsten Carbide Blades

Tungsten Carbide Band Saw Blades

If you're looking for a versatile, cost-effective and durable saw blade that generates a clean cut like no other, a tungsten carbide bandsaw blade may be just what you have in mind.

There are endless reasons to consider adding this tool to your arsenal. It outlasts steel in terms of sharpness, efficiency and performance. It provides an excellent return on investment and handles a variety of materials and cutting tasks. It can even take on high temperatures and abrasive materials.

Learn more about the advantages of tungsten carbide blades and the different products we offer at DoALL Sawing Products.

Why Choose Tungsten Carbide Bandsaw Blades From DoALL Sawing Products?

Tungsten carbide saw blades are optimal for harder and/or abrasive applications that generate high cutting temperatures and quick tool wear. These blades are nearly twice as hard as steel, giving them a much longer life span than many standard blade varieties.

At DoALL, we create our tungsten carbide blades using a proprietary component mix steel body. We also use tungsten carbide material on the blade teeth. These blades are incredibly abrasion-resistant, withstanding much higher temperatures than their bi-metal counterparts. These unique features make the blades perfect for cutting materials that pose challenges to many conventional bandsaw blades.

Types of Tungsten Carbide Blades We Offer

At DoALL, we understand that some cutting tools need to go above and beyond the performance of most standard blades. That's why we offer several options, each with a unique set of benefits. Our carbide bandsaw blade selection includes:

1. STC

Our STC tungsten carbide blades work well for cutting highly abrasive materials that usually dull bi-metal blades quickly, like aluminum castings, fiberglass, graphite and more. They can effectively resist rapid tool wear caused by the quick cutting of these abrasive materials. The STC Tungsten Carbide features a positive rake angle and tungsten carbide tooth.

2. T3N

Our T3N tungsten carbide blades with their negative rake angle and tungsten carbide tips are one of the most durable and heat-resistant blades on the market. The triple-chip negative rake can seamlessly cut case-hardened materials and ensure a smooth finish.

3. T3P

The T3P tungsten carbide blade is a production workhorse, providing some of the highest cutting capacities for heavier substrates like nickel, titanium and many superalloys. This carbide bandsaw cutting blade provides impeccable heat resistance, yielding a smooth finish despite its aggressive sawing capabilities.

The T3P features a tungsten carbide tooth and a triple-chip positive rake angle, allowing it to take on even the most demanding materials and production rates. Consider the T3P blade if you need a reliable solution for your production sawing applications.

4. T7P

Our T7P tungsten carbide blade features superior cutting and heat resistance for larger sized parts.. These qualities allow for enhanced penetration of the toughest materials, including high-nickel alloys, titanium and large-diameter superalloys. It features a positive rake angle, tungsten carbide tooth and seven-grind pattern. Like the T3P blade, the T7P produces a smooth finish despite its aggressive cutting.

Tungsten Carbide Blade Applications

Knowing you have the right blade on your bandsaw is critical when you're cutting through challenging materials. Our tungsten carbide blades serve various applications across many industries. Some standard cutting applications of these blades include:

- Cast aluminum.

- Inconel.

- Monel.

- Hastalloy.

- Fiberglass.

- Graphite.

- Case-hardened rods.

- Titanium.

- Superalloys.

Benefits of DoALL Tungsten Carbide Blades

Our tungsten carbide blades are among the toughest, most reliable and durable cutting tools of their kind. Our strict engineering and manufacturing processes ensure these blades meet the industry's highest quality standards and provide a wealth of benefits:

- Strength and wear resistance: Tungsten carbide saw blades are great for materials that quickly degrade conventional blades. They can effectively resist friction, corrosion, rust, and general wear.

- Long service life: Due to their robust construction, tungsten carbide blades usually have a longer life span than most traditional bi-metal blades. They also tend to stay sharper longer.

- Cost-effectiveness: These blades are extremely economical, providing an outstanding return on your investment. Their strength, durability and life span make them well worth the initial purchase.

- Heat resistance: Tungsten carbide blades have excellent thermal resistance, allowing them to perform well at very high temperatures.

- High-quality cutting results: Tungsten carbide blades generate clean cuts and superior finishes, yielding the results you desire. They can minimize the need for post-cutting processing.

- Quality construction: The superior blade design reduces the load on the tool while cutting.

- Versatility: You can use our tungsten carbide blades for a variety of materials and projects. Whether you're working with aluminum, fiberglass, titanium, high nickel alloys, exotics or graphite, you can easily find the tungsten carbide blade you require from our selection.

Buy From One of the Top Tungsten Carbide Bandsaw Blade Manufacturers

If you need to cut a superalloy that demands more than the capability of your standard bandsaw blade, choose DoALL's tungsten carbide blades. We are the only company in the industry that provides all four sawing solutions under one roof — blades, machines, fluids and services.

Our knowledgeable team is ready to help you determine whether these blades are a good fit for your application and which type might be the best option. Whatever your project specifications or the materials you're working with, we have decades of expertise to help you find the right solution.

Interested in learning more about our products or making a purchase? Fill out our quote form today for pricing or more information!