Cutting Fluids

Cutting Fluids: Essential for Your Sawing Machines

When it comes to your sawing machines, it's vital to have the materials necessary to keep them functioning with optimal efficiency for years to come. Bandsaw cutting oil plays a major role in ensuring your saws deliver satisfactory results while standing the test of time. Explore the metal bandsaw cutting fluids we offer below.

Keep Your Blades Lasting Long with DoALL Fluids

At DoALL Sawing Products, we've manufactured cutting and grinding fluids since the 1950s. We offer a broad range of cutting oils like semi-synthetics, synthetics, and soluble oils. Our product line also includes:

- Metalworking and machining coolants and lubricants.

- Direct application machine tool lubricants.

- Hydraulic, transmission, gear, and way/spindle oils.

We strive to provide customers with high-quality, affordable performance fluids to reduce costs and improve operations. We're dedicated to offering environmentally friendly and worker-safe solutions to meet all your machining needs. From design through manufacturing, every aspect of this journey involves you — the customer! We are committed to your satisfaction and look forward to serving you.

Our Cutting Fluids for Bandsaws

Cutting fluids are coolants and lubricants used in metalworking applications. These oils reduce friction and prevent heat generation during the metal cutting process, subsequently improving cutting conditions and prolonging tool life.

At DoALL, we carry a comprehensive assortment of cutting oils designed to facilitate the cutting process and produce the most accurate results. Our vast inventory of bandsaw cutting oils includes:

1. Straight Oil

Straight oil cutting fluids offer optimal lubrication with the lowest cooling capacity. They are commonly used in heavy cutting and grinding operations. Our straight oils are 90% oil and don't emulsify in water. We formulate these blends with extreme pressure additives for maximum surface finish and cutting tool life. They're ideal for applications with high lubricity requirements, as well as when machine speeds are low enough that they don't warrant cooling action.

2. Soluble Oil

Soluble oil provides reliable lubrication for water-miscible fluids. It is used for machining ferrous and non-ferrous metals when a high cooling capacity is necessary. Water-soluble fluids are eco- and operator-friendly and emit a far less pungent odor than other oil types. They form a strong water and oil emulsion to preserve your cutting tools and surface finish. Additionally, they offer superior rust protection and accommodate a wide range of applications and materials. Another perk is that water-soluble oils tend to be more cost-effective. DoALL has a variety of water-soluble cutting oils, including ones suitable for cast iron, stainless steel, superalloys, and more.

3. Synthetic Liquid

Synthetic fluids are water-based, meaning they easily dissolve in water and don't contain oil. They have excellent cooling properties and are often used for fine grinding applications. Synthetic cutting fluids have low density and a higher concentration of additives, allowing them to perform reliably for years. They're also highly resistant to heat, viscosity breakdown, and oxidation.

Some other benefits of our synthetic fluids include:

- Keeping your material cool despite high cutting speeds.

- Flushing chips away from the cutting zone quickly.

- Decreasing thermal distortion for better cutting accuracy.

- Maintaining effective flow even in extreme temperatures.

- Resisting corrosion.

4. Semi-Synthetic Fluids

Semi-synthetics offer dependable stability, lubrication, and cooling performance. Their small oil concentration lets heat dissipate quickly, enhancing both the quality of the cut and the tool's service life.

To ensure high-quality lubricity and corrosion resistance, we develop our semi-synthetic fluids using highly advanced technology and ingredient blends. We use extreme pressure additives and frictional modifiers in many of our formulas to prevent wear and tear on your tools and equipment.

They're also versatile and economical and can keep your machinery and workspace clean. As another benefit, our synthetic cutting fluids are available in multiple container sizes for your convenience.

5. Direct Application Oils

We offer two direct application oils for specific applications where flood coolants are prohibited or not required. These oils are used with an air-driven application system, producing "dry" chips as the fluid is used up during the cutting operation.

- AL-2000 Micro Lubricant

- AL-2100 Mist Lubricant

These fluids create a high-strength molecular coating on the cutting edge, reducing friction and extending tool life. They contain no petroleum, sulfur, or chlorine and are non-toxic, non-flammable, and non-polluting. They’re perfect for use in air-driven spray mist systems or Maximum Quantity Lubricant (MQL) equipment.

6. Machine Lubricants

We offer a range of lubricants for machining applications, including:

- ATF (Automatic Transmission Fluid)

- Hydraulic Oils

These lubricants are designed to provide superior performance, ensuring smooth operation of your machinery and preventing wear and tear over time. Both ATF and hydraulic oils are essential for maintaining the efficiency and longevity of your equipment.

7. Specialty Fluids

We also offer Tool Saver lubricant sticks, designed to enhance surface finish, reduce overall production costs, and lower power consumption.

Applications of Bandsaw Cutting Oils

Cutting fluids are primarily used in metalworking and machining operations, such as milling, turning, broaching, and sawing. Though these oils are somewhat industry-specific, they have many versatile applications. Machine cutting oils are often used for:

- Lubricating tooling.

- Cooling tools and workpieces.

- Cleaning machining areas.

- Flushing chips from the cutting zone.

- Reducing friction.

- Improving surface finish.

- Preventing rust formation.

- Preventing build-up edge (BUE) formation.

Benefits of Using Machine Cutting Oil for Bandsaws

When you invest in cutting fluids for your machining processes, you'll experience all the advantages of these valuable substances, including:

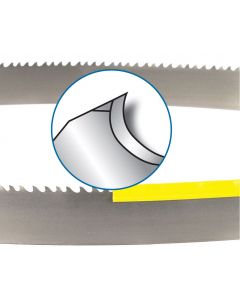

- Prolonged tool life: Cutting fluids cool the cutting edge and reduce cutting tool wear, increasing machine lifespan.

- Better surface finish: Cutting oil prevents tool seizure and galling to achieve a better-machined surface finish.

- Reduced power consumption: Using networking oils prevents friction and reduces machining forces, saving energy by minimizing power consumption.

- Surface protection: Machining oils have anti-corrosion properties, helping safeguard machined surfaces from rust.

- Chipping prevention: Bandsaw cutting oils reduce tool-chip friction by acting as a lubricating barrier.

- Distortion elimination: Cutting fluids act as coolants, cooling workpieces to prevent distortion from heat generation and maintain dimensional accuracy.

Purchase Bandsaw Cutting Fluids and More From DoALL Today

You can ensure the highest-quality cutting outcomes with machine cutting oils from DoALL. With over 97 years of experience in the manufacturing industry, we're considered industry leaders in sawing product production. We're proud to be the only manufacturing company in the world that creates sawing fluids, machines, and blades. When you come to us, you can trust that we have the extensive knowledge necessary to help you secure the products that best serve your individualized needs.

If you would like to request a quote for our bandsaw cutting fluids, fill out a form, and one of our professionals will be in touch with you shortly!