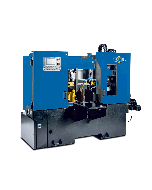

DC-510CNC - Dual Column Enclosed CNC Band Saw

Machine Capacity: w 20” x h 20" (510mm x 510mm)

Machine Capacity Round: 20″ (510mm)

Production Level: High

Standard Features: Fully-Automated Siemens Controller, Dual Index Vise Jaws for Work Handling and Independent Drive Motors for Band, Hydraulics & Coolant Pump.

The DC-510CNC Hercules™ high production metal cutting band saw from DoALL is designed to work well in industrial settings, where a fully automated solution is required. This saw is ideal for large metal parts production across any industry vertical.

Thanks to the robust construction of the DC-510CNC it is possible to cut a wide range of full and profile materials including stainless and tool steel.

The "box" or enclosed design provides a safer environment for both the operator, and other employees on the production floor. The DoALL DC-510CNC can be customized through the world class control system and various available optional accessories to meet your specific needs. Make sure to request a quote and one of our sawing specialists will help spec out the perfect machine.

Standard equipment included with your new DoALL DC-510CNC is as follows:

- Siemens control with touch screen display

- Automatic feed control with programmable feed rates

- Work light

- Worm chip conveyor for long chips including chip pan

- Variable vise pressure control - Set of 2

- Dual acting index vise jaws for crooked stock

- Hydraulic band tension

- Automatic retraction of material in cycle for protection of carbide blade

- Power-driven band brush

- Flood coolant

- Work height sensor

- Automatic guide arm setting

- One (1) complimentary DoALL bi-metal saw blade

- Programmable work height

- Tool kit

- Complimentary DoALL cutting fluids package

- Smart programming to automatically select cutting parameters based on material size and type

- Operation and parts manuals on CD or USB data stick

Machine Specs:

- Cutting capacity for tube - Round: 20" (510mm), Rectangle: 20” x 20" (510mm x 510mm)

- Cutting capacity for solid - Round: 20" (510mm)

- Maximum nesting capacity – w 19.6” x h 17.7" (500mm x 450mm)

- Minimum nesting capacity - 3" (75mm)

- Band saw blade dimensions - Width: 2” x 0.063" (54mm x 1.6mm), Length: 239" (6060mm)

- Band speed - 50-262 fpm (15-80mpm)

- Auto index single stroke min-max - 0.12-26.4" (3-670mm)

- Auto index multiple stroke max - 394" (9999mm)

- Minimum butt end - 4.7" (120mm)

- Band drive motor - 10 HP (7.5kw) 25 degree sloped

- Hydraulic pump – 2HP (1.5kw)

- Coolant pump and capacity - 1/4 hp (0.12kW), 13-1/4 gal (50 lit)

- Multiple feed - 393.7" (9999mm)

- Material pass line height - 32" (810mm)

- Machine weight – 13,713lbs (6220kg)

- Dimensions W x L X H – 150” x 95” x 87" (3800mm x 2400mm x 2200mm)

- Machine Voltage - 460vac, 3-Phase, 60hz, Wye configuration required

Optional Accessories:

- Mist-style saw band lubrication

- Laser line generator

- Retractable stationary machine vice jaw

- Dynamic adjustment of feed rate to ensure cut square-ness

- Laser edge finder, eliminates trim cut

- 3 ft. (1000mm) Input or output conveyor with drip pan/gutter - 20" (510mm) cylinder width - 1142 lbs/ft (1700kg/m) capacity

- 3 ft. (1000mm) Output conveyor for with drip pan/gutter - 20" (510mm) cylinder width - 1142 lbs/ft (1700kg/m) capacity

- Powered hydraulic lift conveyor cylinder with a 24.4" (620mm) cylinder width

- 3 ft. (1000mm) Extreme heavy-duty conveyor with one (1) vertical roller - 22.5" (570mm) cylinder width - 1344 lbs/ft (2000kg/m) capacity

- 6 ft. (2000mm) Extreme heavy-duty conveyor with one (1) vertical roller - 22.5" (570mm) cylinder width - 1344 lbs/ft (2000kg/m) capacity

- Single fixed heavy-duty vertical guide roller - 25.6" (650mm) height

- Hydraulic front and rear vise nesting - Set of 2 - note that the Work Height Sensor will not work with HP-A

- Single adjustable heavy-duty vertical guide roller - 25.6" (650mm) height

- 6 ft. (2000mm) Input or output conveyor with drip pan/gutter - 20" (510mm) cylinder width - 1142 lbs/ft (1700kg/m) capacity

- Single fixed vertical guide roller - 11" (280mm) cylinder height

- Single adjustable vertical guide roller - Adjusts up to 24.4" (620mm) cylinder width - 11" (280mm) height

- Single adjustable horizontal conveyor roller - 672 lbs/ft (1000kg/m) capacity

- Additional conveyor rollers

- Additional roller table for gap

- Chip pan with drain

- Handle for chip box

- Cut piece collection box with drain

- Wear parts service kit - Lead-in bearings, carbide guide inserts, insert screws, band brushes

- Magnetic wand chip remover

- DoALL Cut Above 10 Year Warranty