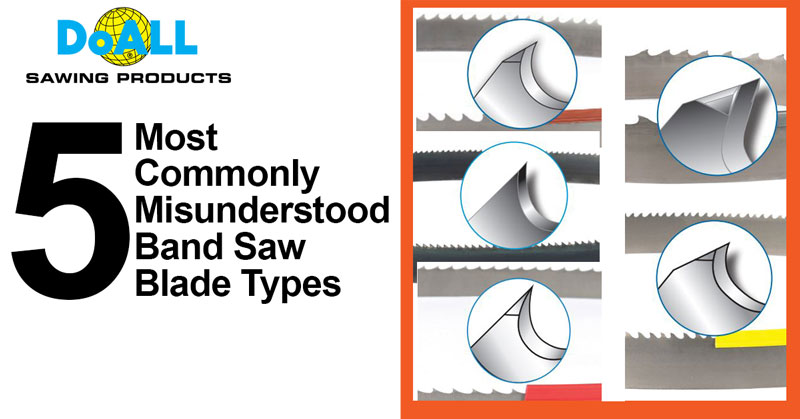

DoALL Sawing Experts Share The 5 Most Commonly Misunderstood Band Saw Blade Types

DoALL Sawing Experts Share The 5 Most Commonly Misunderstood Band Saw Blade Types

Ever wondered why choosing the right band saw blade is crucial for your industrial cutting operations? It can be overwhelming with the abundance of online information available. In the world of industrial sawing, selecting the correct tool is crucial. The correct band saw blade choice can make all the difference between flawless parts and costly errors. However, this vital tool is often misunderstood. DoALL Sawing experts have identified the five most misunderstood band saw blade types and offer insights to guide you towards informed decisions.

1. Bi-Metal Blades

Misunderstanding: Many believe bi-metal blades are suitable for all materials and cutting tasks.

Reality: While bi-metal blades are incredibly versatile and durable, they're not always the best choice for every material or cutting application. They excel in cutting a variety of metals, such as steel and non-ferrous materials. However, for extremely hard or abrasive materials, like titanium or hardened steel, a carbide-tipped blade might be more suitable. For expert guidance tailored to your specific operation, connect with a DoALL professional to determine if bi-metal blades are the optimal choice for your operational needs.

2. Carbide-Tipped Blades

Misunderstanding: These blades are often thought to be indestructible and suitable for all cutting applications.

Reality: Carbide-tipped blades are indeed very durable and can cut through extremely tough materials like high nickel alloys and titanium. However, they are also more expensive and can be overkill for certain materials, such as mild steel. Achieving optimal performance with carbide blades requires specific operational techniques and care to avoid damaging the teeth. For personalized advice on integrating carbide-tipped blades into your operations effectively, connect with a DoALL sawing expert today.

3. Carbon Steel Blades

Misunderstanding: Some users assume carbon steel blades are inferior and should only be used for basic or non-precision tasks.

Reality: Did you know? The carbon steel blade was DoALL’s pioneering invention back in 1927, marking a significant milestone in industrial sawing. This original blade type remains highly effective for cutting wood, plastic, and various metal types. While not as durable as bi-metal or carbide-tipped blades, carbon steel blades offer a cost-effective solution for a wide range of applications. Discover if this blade type is ideal for your cutting operation and experience firsthand the unmatched quality of our original innovation. Connect with a DoALL sawing expert today to learn how carbon steel blades can optimize your cutting processes and drive efficiency in your operations.

4. Variable Pitch Blades

Misunderstanding: Users do not understand the difference between variable and single pitch blades. Users also have some difficulty understanding when to use one or the other.

Reality: Variable pitch blades feature teeth and gullets of varying size and depth, reducing vibration and eliminating the "whine" during cutting. This design makes them ideal for cutting solids, structural materials, tubing, and bundles, delivering superior finishes on a wide range of metals. They excel in reducing chatter and extending blade life in demanding cutting applications. Explore whether variable pitch blades are the right choice for your operations and enhance your cutting efficiency. Connect with a DoALL sawing expert today to discover how variable pitch blades can elevate your cutting processes and maximize productivity.

5. Single Pitch Blades

Misunderstanding: Single pitch blades are obsolete and “old school”.

Reality: Single pitch blades, with their consistent tooth spacing, excel in general-purpose cutting of smaller and thinner materials, delivering clean, precise cuts across wood, plastic, and numerous metal types. Discover how single pitch blades can optimize your cutting processes and maximize equipment lifespan. Connect with a DoALL sawing expert today to find the perfect blade for your needs and elevate your operation's performance.

Understanding the nuances of different band saw blade types is crucial for optimizing cutting efficiency, and achieving precise results in industrial applications that increase your bottom line. DoALL Sawing experts can guide you in selecting the right blade for your specific needs. No matter the material or production volume, choosing the appropriate band saw blade will help you achieve the best possible results while maximizing the lifespan of your equipment, making your operation more efficient and profitable. Connect with a DoALL sawing expert today to explore how these insights can elevate your cutting processes and streamline your operations effectively.

Connect With Us:

Have questions or want to delve deeper into the world of blades crafted for businesses like yours? Don't hesitate to reach out! We're here to answer all your queries and provide you with the specialized knowledge you need for your metalworking success. Trust DoALL, the industry leader, to provide you with the tools you need to succeed.