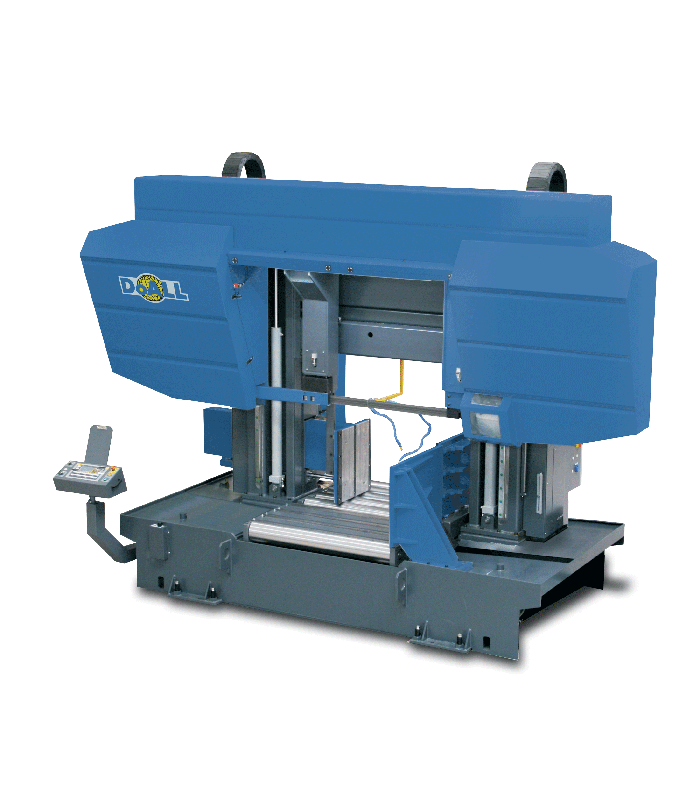

Hercules™

DC-1400CNC - Dual Column Table Band Saw

Machine Capacity: 47 x 55″ (1200 x 1400mm) | Round (Tube or Solid): 47″ (1200mm)

Production Level: High

The DC-1400CNC Hercules™ high production, horizontal CNC band saws from DoALL are highly efficient, automatic, hydraulically controlled machines with multiple material feeds. Designed for vertical cuts, the DC-1400CNC is ideal for serial production in industrial settings. Thanks to the robust construction of the DC-1400CNC, it is possible to cut a wide range of full and profile materials including stainless and tool steel. In addition, the "box" or enclosed design provides very safe operation. A large variety of optional accessories are available to customize the machine for specific sawing requirements.

SKU

DC-1400CNC

Standard Equipment:

- Siemens saw control

- Work light

- Hydraulic band tension

- Automatic guide arm setting

- Automatic feed control with programmable feed rates

- Variable vise pressure control - Set of 2

- Power-driven, band brush

- Chain chip conveyor with large pan

- Automatic retraction of material in cycle for protection of carbide blades

- Dual acting index vice jaws for crooked stock

- Retractable stationary machine vice jaw

- Set up tools

- Complimentary DoALL cutting fluids package

- One DoALL bi-metal saw blade

- Instruction and parts manuals on CD or USB data stick

- Cutting Capacity Round (Tube or Solid): 47.25″ (1200mm)

- Cutting Capacity Rectangle: 47.25 x 55.12″ (1200x1400mm)

- Maximum BNesting Capacity: 47.25 x 31.5″ (1200x800mm)

- Auto Index Stroke Length: 0.4-39.4" (10-1000mm)

- Band Saw Blade Width: 3.15 x 0.063″ (80x1.6mm)

- Maximum Blade Length: 458.7″ (11650mm)

- Band Speed: 50-262 fpm (15-80mpm)

- Band Drive: 15 hp (11.1kW)

- Hydraulic Pump: 5.4 hp (4kW)

- Coolant Pump: 0.2 hp (0.155kW)

- Material Pass Line Height: 18" (460mm)

- Machine Weight: 55116 lbs (25000kg)

- Dimensions W x L x H: 205 x 93 x 113" (5200x2700x2850mm)

Optional Accessories:

- Front and rear vise nesting - Set of 2

- Laser edge finder - eliminates trim cut

- Dynamic adjustment of feed rate to ensure cut squareness

- Mist-style saw band lubrication

- Laser line generator

- Large chip pan with drain

- Input or output roller conveyor with drip pan - 4409lbs/3.28' (2000kg/m), 31.5x39.3″ or 31.5x78.7″ (800x1000 or 800x2000mm)

- Single fixed or movable side vertical guide roller - 31.5″ (800mm)

- Hydraulic shift of vertical guide roller

- Additional conveyor rollers

- Filler plates - 39.3 or 78.7″ (1000 or 2000mm)

- Heavy-duty input or output roller table - 15432lbs/3.28' (7000kg/m), 31.5x78.7″ (800x2000mm)

- Wear parts service kit

Please note that some accessories require extra lead time due to factory installation.