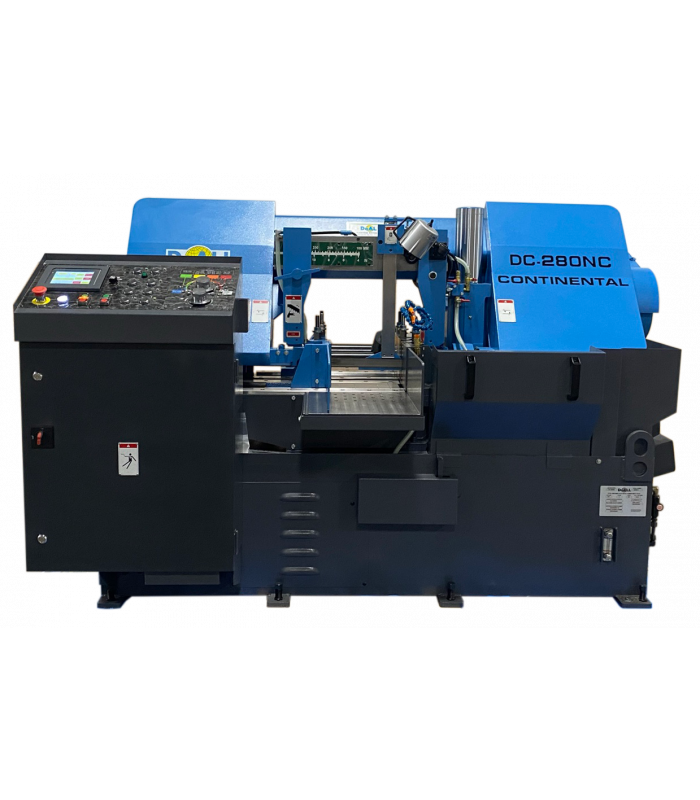

DC-280NC Production Band Saw

Machine Capacity: w 11.75” x h 11" (300mm x 280mm)

Production Level: High

Machine Capacity: Round 11" (280mm)

The DoALL DC-280NC Continental Series™ high production, horizontal band saw by DoALL is designed for cutting a wide range of metals. The DC-280NC offers fully-automatic operation via a PLC digital control panel and features a solid, heavy-duty construction.

The DC-280NC is a tried-and-true favorite for our customers working in high production applications such as aerospace, automotive, primary metal centers and parts production plants. It is both affordable and robust – making it the leading choice for production houses looking to maximize ROI.

Standard equipment included with your new DoALL DC-280NC band saw is as follows:

- Programmable logic controller for all machine functions

- Feed rate and feed force saw head control

- Infinite band speed controlled by a variable frequency drive

- Hydraulic retractable shuttle vice indexer on chrome rails

- Rapid and creep speed index vice control

- Multi-step full stroke cylinder with a split front vice clamping fore and aft of cut

- Variable vice pressure control

- Vertical hydraulic cylinders with hold down fixtures

- Spring loaded, zero clearance, coolant through, carbide faced saw guide inserts with lead in rollers

- Adjustable power driven band cleaning brushes with coolant flush line attached

- Halogen work light

- Flushing hose for machine wash down and auxiliary coolant nozzles.

- Hydraulic band tension.

- Hydraulic adjustable speed auger design chip conveyor.

- Saw band break/stall motion detector shut off switch.

- Band door interlocks.

- Operation and parts manuals on USB stick.

- One 6.5 ft. (2M) idler input conveyor.

- Maintenance tool kit.

- Complimentary DoALL Cutting Fluids package.

- One (1) complimentary DoALL Bi Metal saw blade.

Machine Details & Specs:

Touch Screen Control

Easy operator input - with ability to store 20 unique jobs. Control is multi-lingual for today's diverse workforce. It will display error message when incorrect entry is made. Easy switching between imperial or metric units.

High Efficiency Transmission

High efficiency worm gear box built to decrease wear and transmit full torque to the saw blade. Double wide “V” belt to avoid slipping, transmitting full motor power to the transmission.

Hydraulic Chip Conveyor

Adjustable speed auger-style conveyor allows for coolant to drain from chips before extraction.

Coolant Thru Carbide Faced Saw Guide Inserts

Supplies coolant to the blade evenly before and after the cut creating straighter cuts and allowing longer blade life due to coolant being supplied at the tooth tip.

Efficiently Designed Hydraulic System

Engineered low pressure system allows for smoother and quieter operation which aids in longer component life and easy accessibility for maintenance.

Band Wheels

40 Degree lay back head design minimizes band twist reducing band fatigue. This lay back also allows for a smaller footprint. Flange cast steel wheels insure band tracking to prevent tooth set lost.

Multi-step Full Stroke Vises with Split Front Vise and Variable Vise Pressure

Shorter hydraulic cylinders reduce the overall footprint combining the advantage of rack and full stroke. Split front vice clamps on both sides of the blade reducing vibration and remnant length. Variable Vise Pressure will prevent distortion in thin wall tubing and extrusions.

Hydraulic Blade Tension

Automatically adjusts to correct tension eliminating possible error of over/under tightening the band for maximum cutting rates and band life.

Back-up Bearing/Inserts

Supports the back of the saw band allowing aiding in reducing vibration while cutting and increasing blade life.

Retractable Shuttle Type Index Vise

Both jaws retract when the vise is opened to accommodate the movement of crooked stock increasing accuracy and repeatability.

Magnetic Scale for Indexer

The scale which creates indexing accuracy is protected from dirt and oil build-up ensuring its long life.

Nesting Fixtures

Plug-n-play vertical hold-downs (top clamps) assemblies allows the operator to perform multiple piece cutting to increase productivity.

Warranty

One year parts and service subject to the terms and conditions. Lifetime Warranty available. Please inquire with your representative

Machine specs:

- Saw Blade:

- Width x Length - 1.25" x 150"

- Width x Length - 1.25" x 150"

- Band Drive:

- Motor HP - 5 HP

- Band Speed - 52-430 fpm

- Band Tension – Hydraulic

- Hydraulic System:

- Motor HP - 1 HP

- Reservoir Size 16 Gallon

- Coolant System:

- Flood coolant

- HP - 1/6 HP

- Reservoir Size 21 Gallon

- Indexer:

- Length per Stroke - 15.75"

- Maximum Index Strokes Length - 141"

- Remnant Length - 3.75" (non-bundle)

- Max Nesting Capacity at 90 degrees – 9.88x5.75”

- Floor Space Dimensions:

- W x L X H - 83" x 79" x 51”

- Material Pass Height - 27.5"

- Machine Weight - 3858 lbs.

- Electrical:

- Voltage Requirement - 230V-60Hz-3ph, Wye configuration

- Total Amp Draw (FLA) - 22 Amps

Optional Accessories:

- 10 ft Medium-duty idler conveyor 12" between frames. Roller capacity 850 Ibs.

- 5 ft Medium-duty idler conveyor 12" between frames. Roller capacity 850 Ibs.

- Out of square detection

- Additional USB stick of manuals

- Laser line

- A Nationally Recognized Testing Laboratory (NRTL) is an independent third-part laboratory recognized by the United States Occupational Safety and Health Administration (OSHA) to test and certify products to applicable product safety standards

- DoALL Cut Above 10 Year Warranty Annual Investment